RFID Laundry Products

How TRC Transforms Laundry Services

How does RFID assist keep things like uniforms and towels from becoming lost?

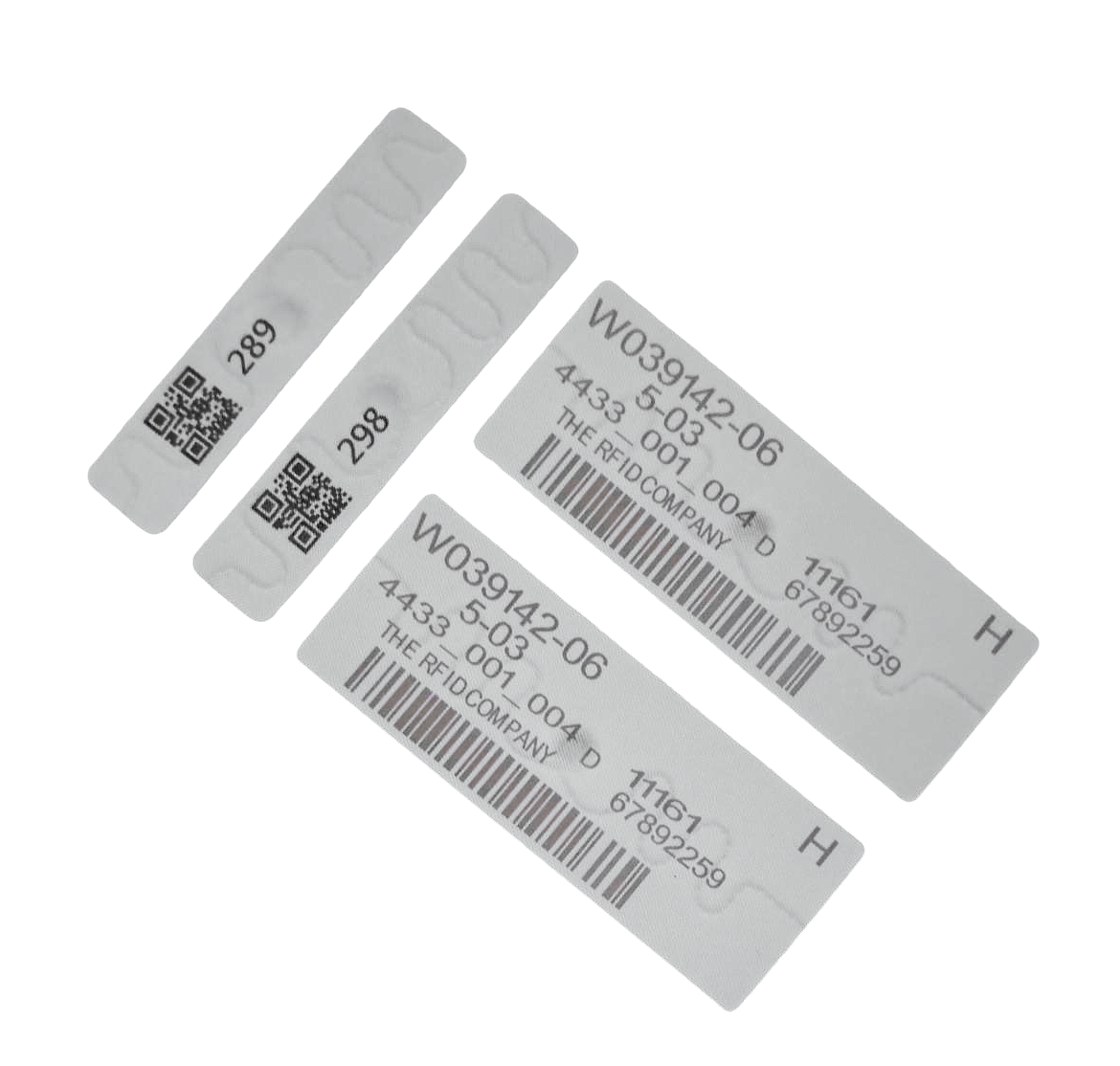

Every item gets a UHF RFID tag that will last a long time. When clothing is being washed, dried, folded, and delivered, it is scanned at each step so you always know where it is.

Will the RFID tags still work after being exposed to extreme heat and chemicals?

Yes. We employ UHF RFID tags that are made for industrial washing, high temperatures, and chemicals.

Do I need to update my current Laundry Management System (LMS)?

No. TRC adds RFID data to your current LMS or ERP, giving you fresh information without messing up your software setup.

Is RFID only good for big washing businesses?

Not at all. RFID works effectively for anything from tiny hotel laundries to big hospitals or uniform rental businesses. No matter what size you are, you get value.

How do I get started with TRC’s laundry RFID solution?

We begin with a site survey and tagging pilot. From there, we help you roll out readers, dashboards, and integration step by step.