RFID Products For Manufacturers

How TRC Transforms Manufacturing Operations

What does RFID keep an eye on in a factory?

RFID can keep track of raw materials, work-in-progress (WIP), tools, containers, and finished goods in real time, across zones, stations, and supply lines.

What is RFID different from barcodes in production?

RFID doesn't need to be in line of sight like barcodes do. It can scan multiple items at once, even through metal or packaging. This makes inventory, audits, and quality checks go faster.

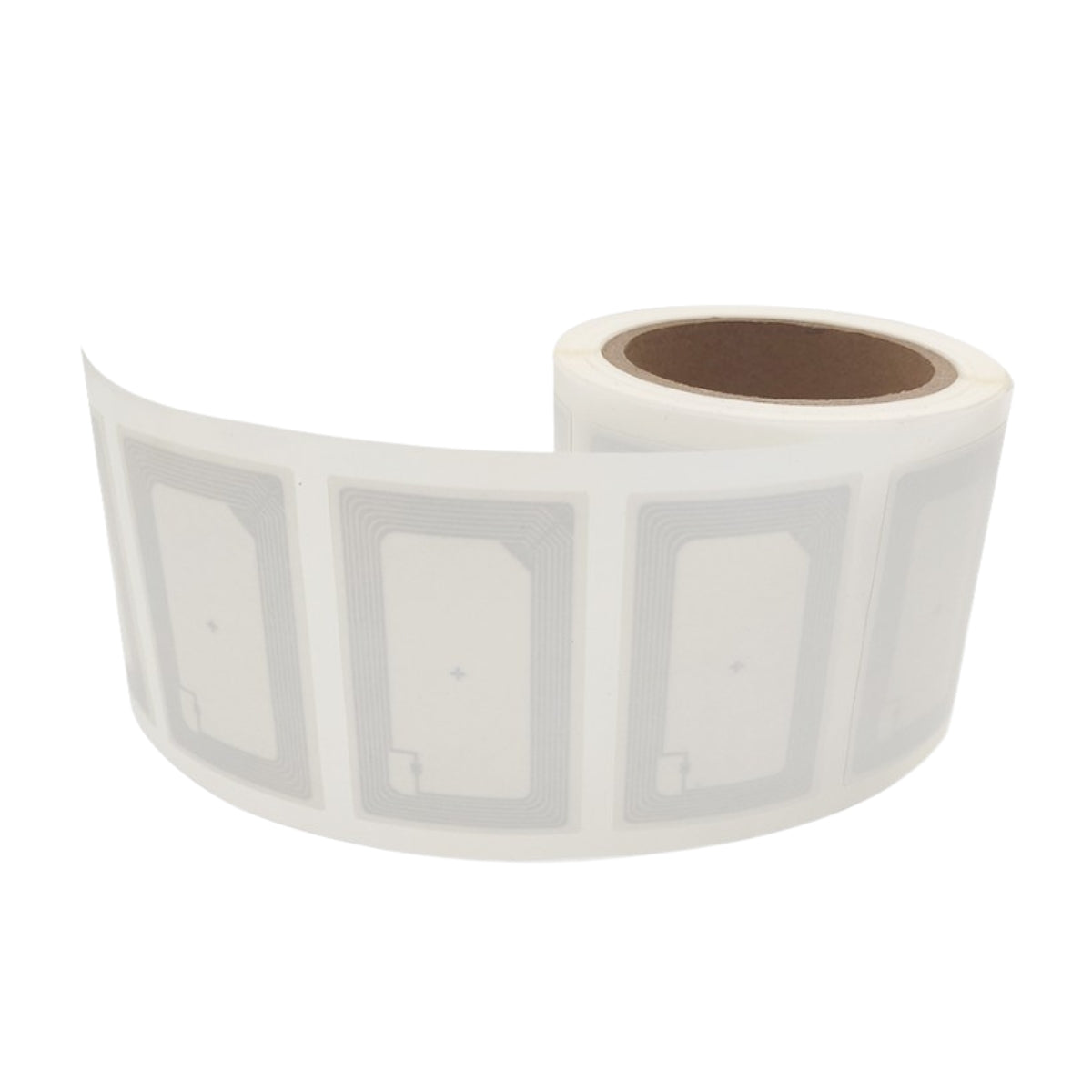

What types of tags perform best in factories?

TRC makes UHF, HF, and on-metal RFID tags that endure a long time and can handle heat, dust, and vibrations, which are common on factory floors.

Can RFID help make fewer mistakes in production?

Yes. RFID makes production more accurate by checking that parts are present, in the right order, and in the right place. This means less delays, fewer things that need to be redone, and better tracking of compliance.

Does RFID help with sustainability goals?

Of course. The TRC sustainable RFID line has tag materials that can be recycled and broken down, making it perfect for green manufacturing efforts.