RFID for Automotive:

Seamless part visibility. Leaner production. Better compliance.

In automotive manufacturing, keeping track of parts across a complex supply chain is a constant challenge. RFID helps solve this by making every component from tyres and windshields to cables and engine parts visible in real time. With RFID in place, you can quickly detect when something is delayed, misrouted, or missing altogether, reducing errors and preventing bottlenecks before they occur.

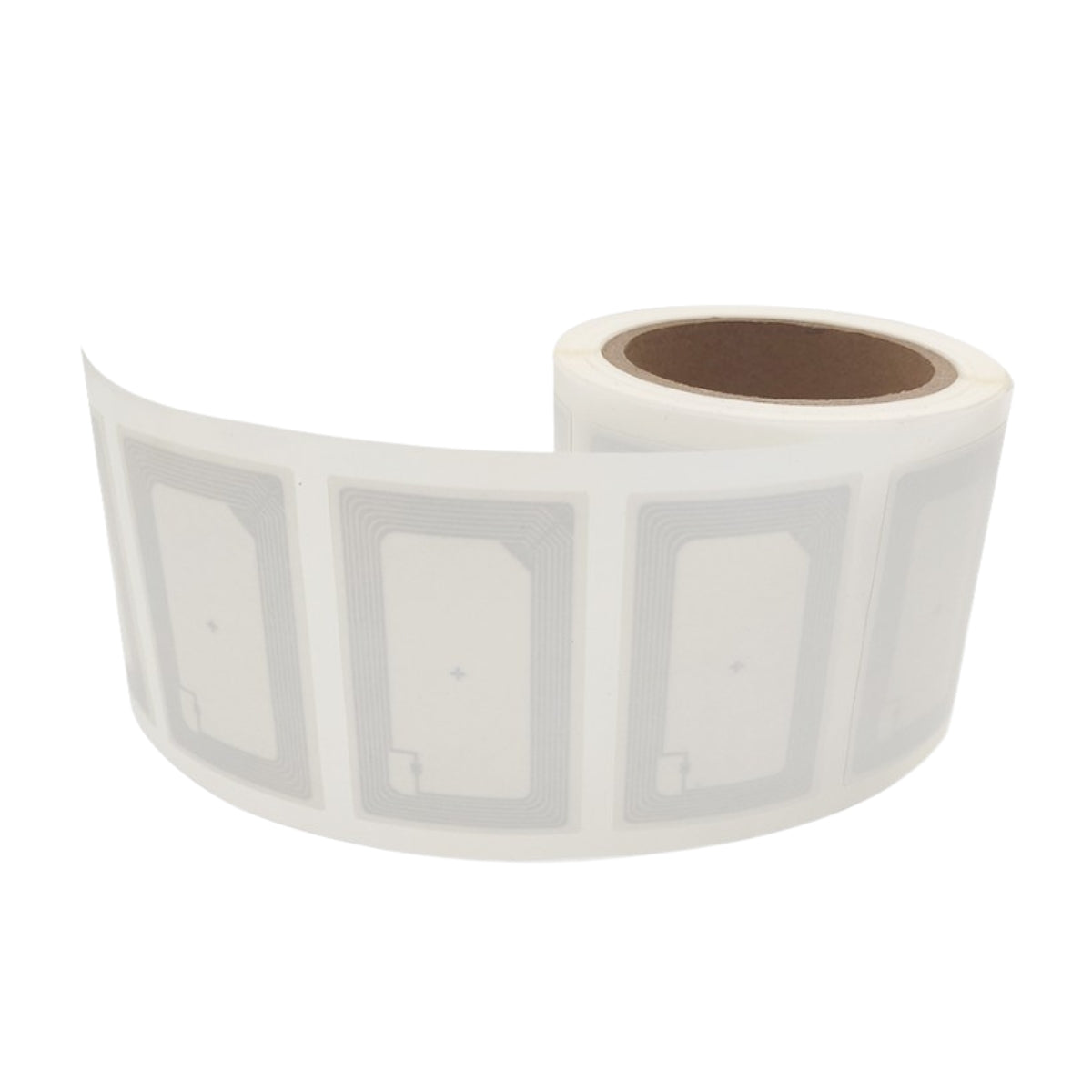

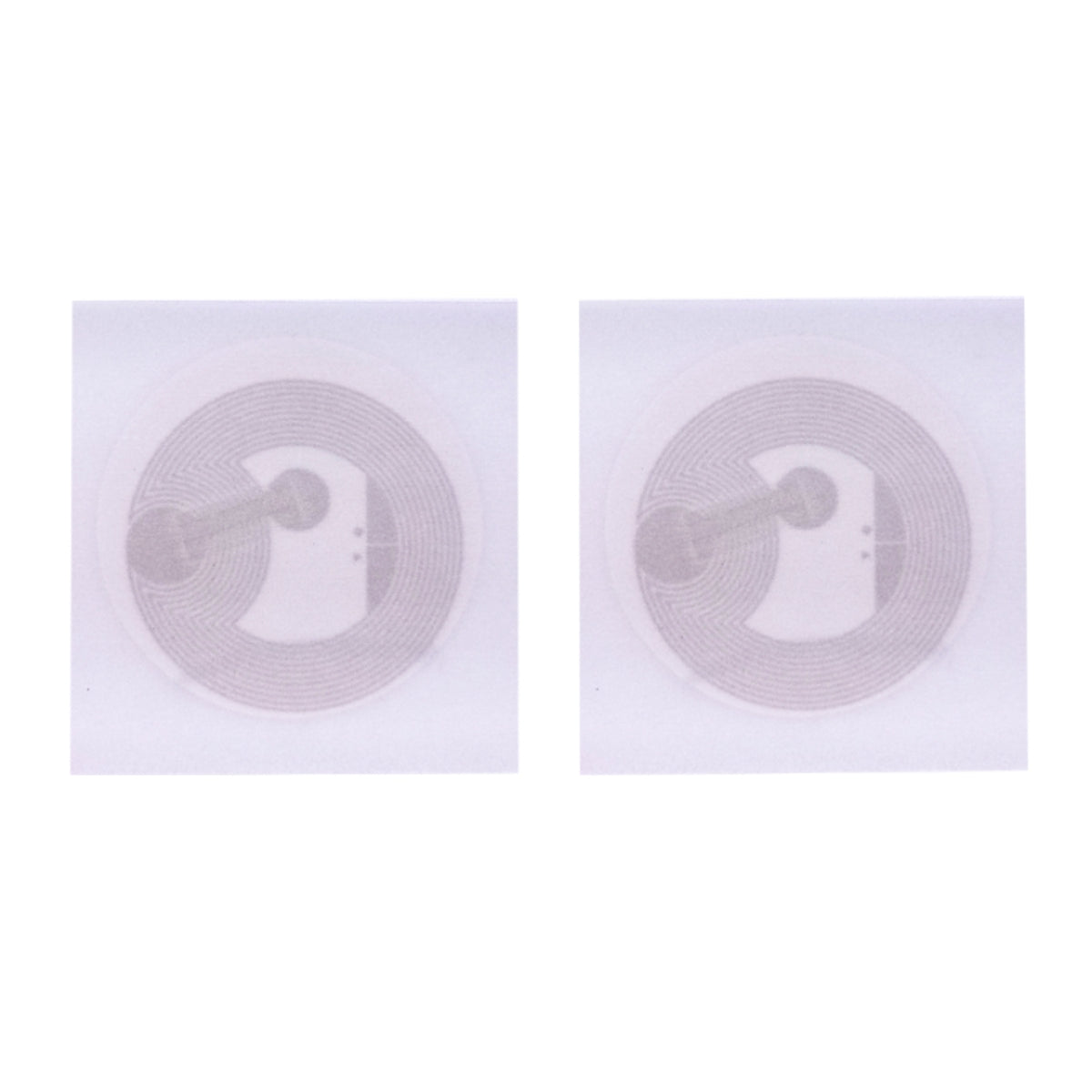

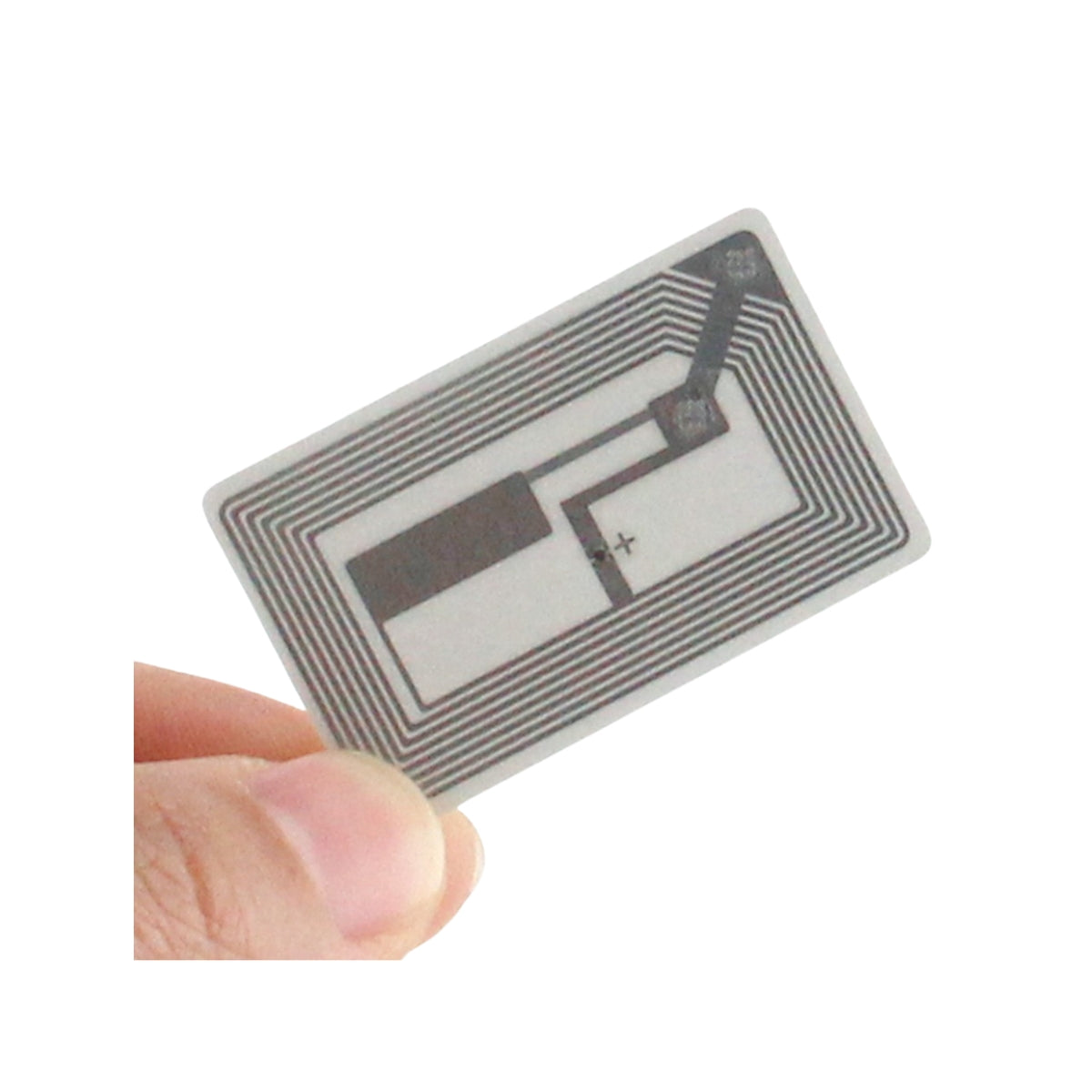

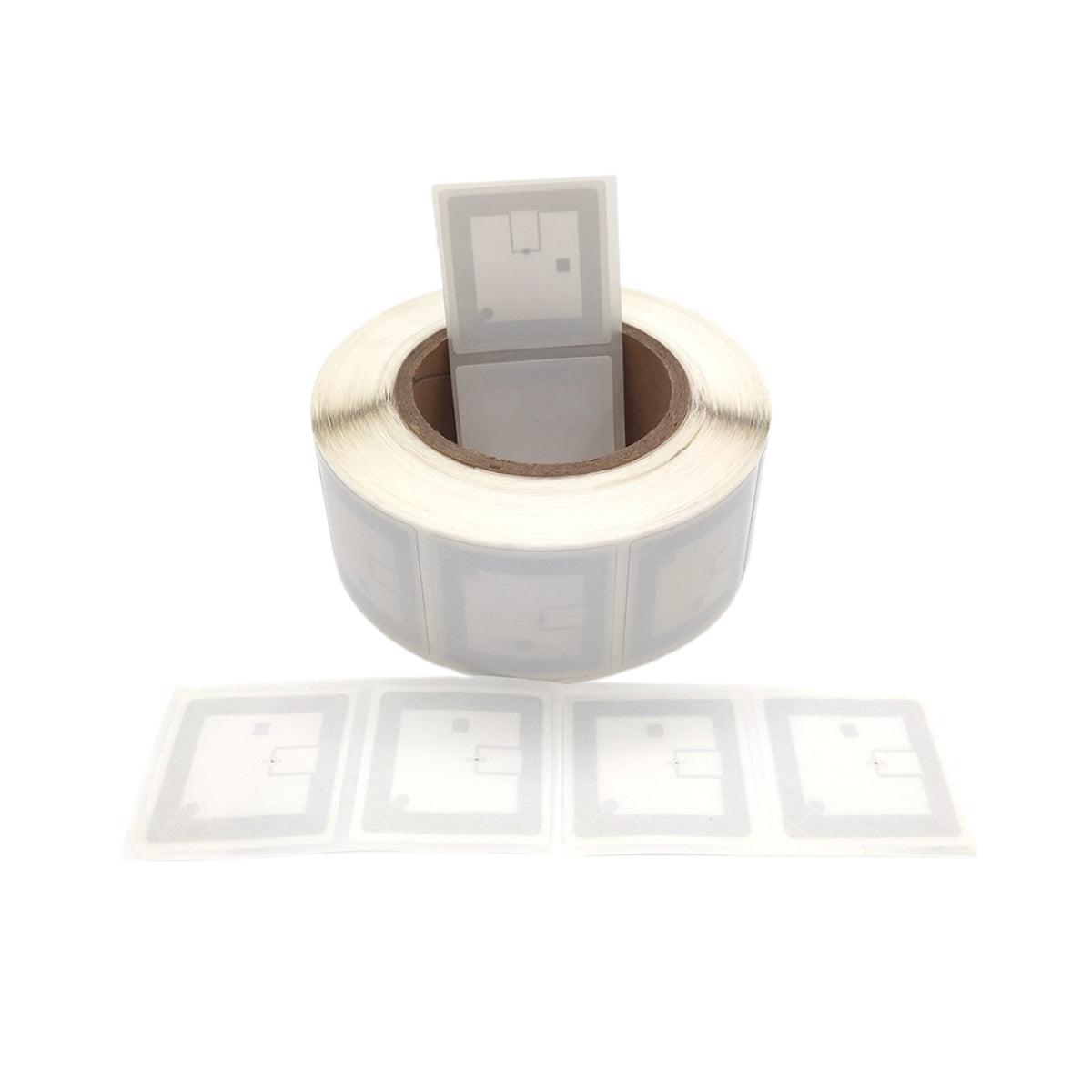

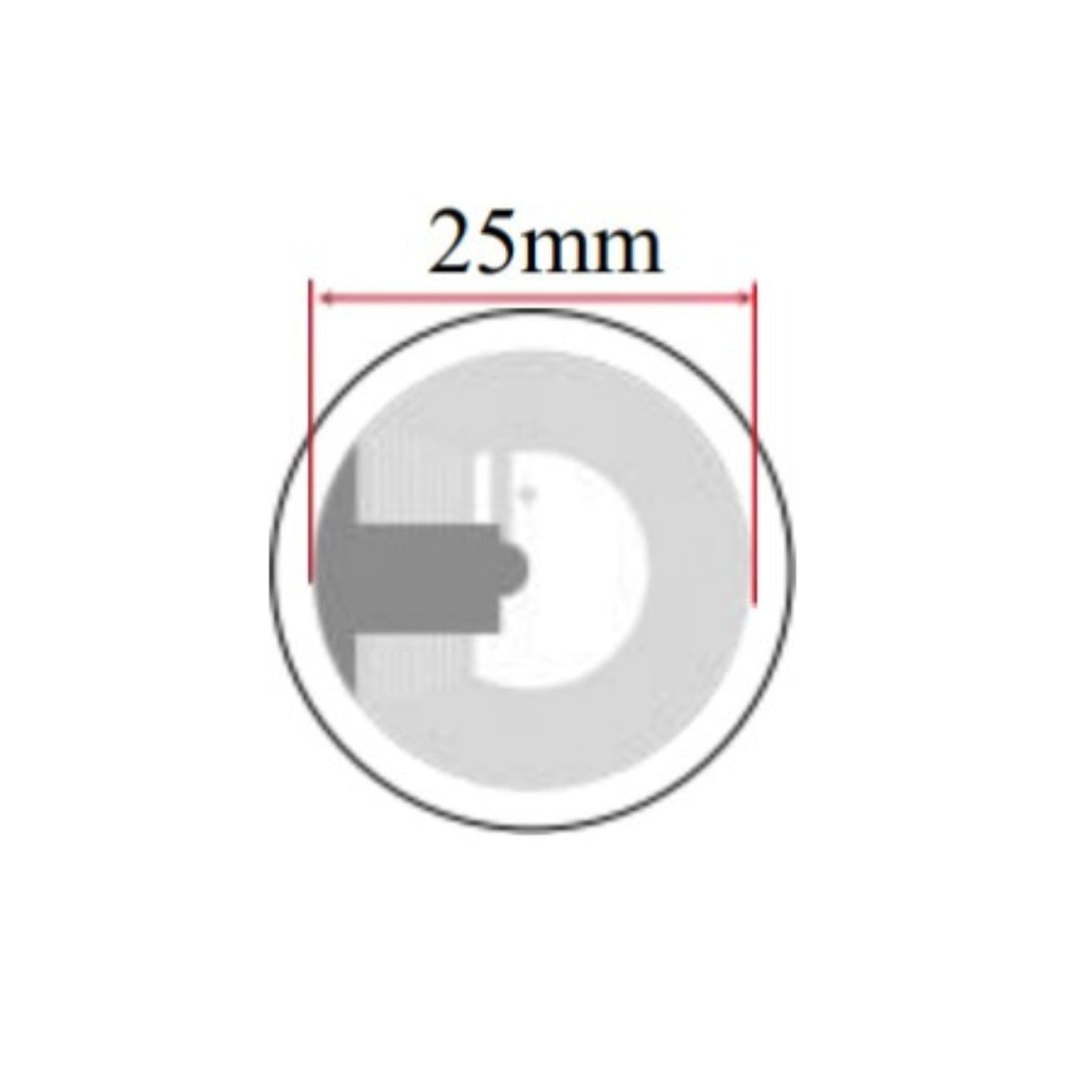

RFID is already a key aspect of making electric vehicles (EVs) today. It helps global OEMs and Tier 1 suppliers keep track of work-in-progress (WIP) more easily. But that's not all it does. The variety of ways to use RFID in cars is growing quickly. TRC makes it easy to set up the proper RFID technology for your workflow, whether it's UHF tags that can survive on metal surfaces or NFC labels that are glued into windscreens.

RFID Products For Automotive Manufacturers

FAQ's

What are the main advantages of employing RFID in the production of cars?

There are several benefits to using RFID in automobile production. For example, it lets you see things in real time, makes assembly more accurate, helps with supply chain coordination, and makes vehicles safer.

Can RFID keep track of parts and pieces of cars in real time?

Yes, for sure. RFID makes it possible to trace every part and piece in the supply chain and on the production line in real time, giving you full visibility and control at every step.

Does RFID make cars safer?

Yes. RFID is what makes modern security features like keyless entry and ignition systems work. These features make it harder for thieves and anyone who aren't supposed to be there to get in.

How can RFID help you keep track of cars and keep them in good shape?

RFID enables you keep track of and identify each vehicle separately. This makes it easy to collect its whole history, arrange maintenance, and make sure it satisfies safety and performance standards.

What are the differences between RFID and barcoding in cars?

Unlike barcodes, RFID doesn't need to be scanned in a line of sight.. It can read more than one tag at a time and work well in tough industrial settings. This makes it great for tracking embedded components and production lines that move quickly.

How TRC Transforms

- TRC enables you see everything that is happening right now, from pallets coming in to electronics that are built in.

- Tags for automobiles and trucks that can handle high temperatures, metal surfaces, and tough environments. These tags work well for paint lines, engine parts, and other things.

- No need to see the line bulk scans and faster audits mean fewer mistakes and more work getting done on your factory floor.

- Ready for connected cars NFC tags put into dashboards or windscreens can be utilised for features, recalls, or servicing data after the sale.

- You may utilise your packaging again in a smarter way. RFID-tagged kitting trays and containers can be found in all of your warehouses and buildings.

- Adding RFID is easy, and advising and integration help make sure it fits with your ERP, MES, or digital twin system without any hassles.