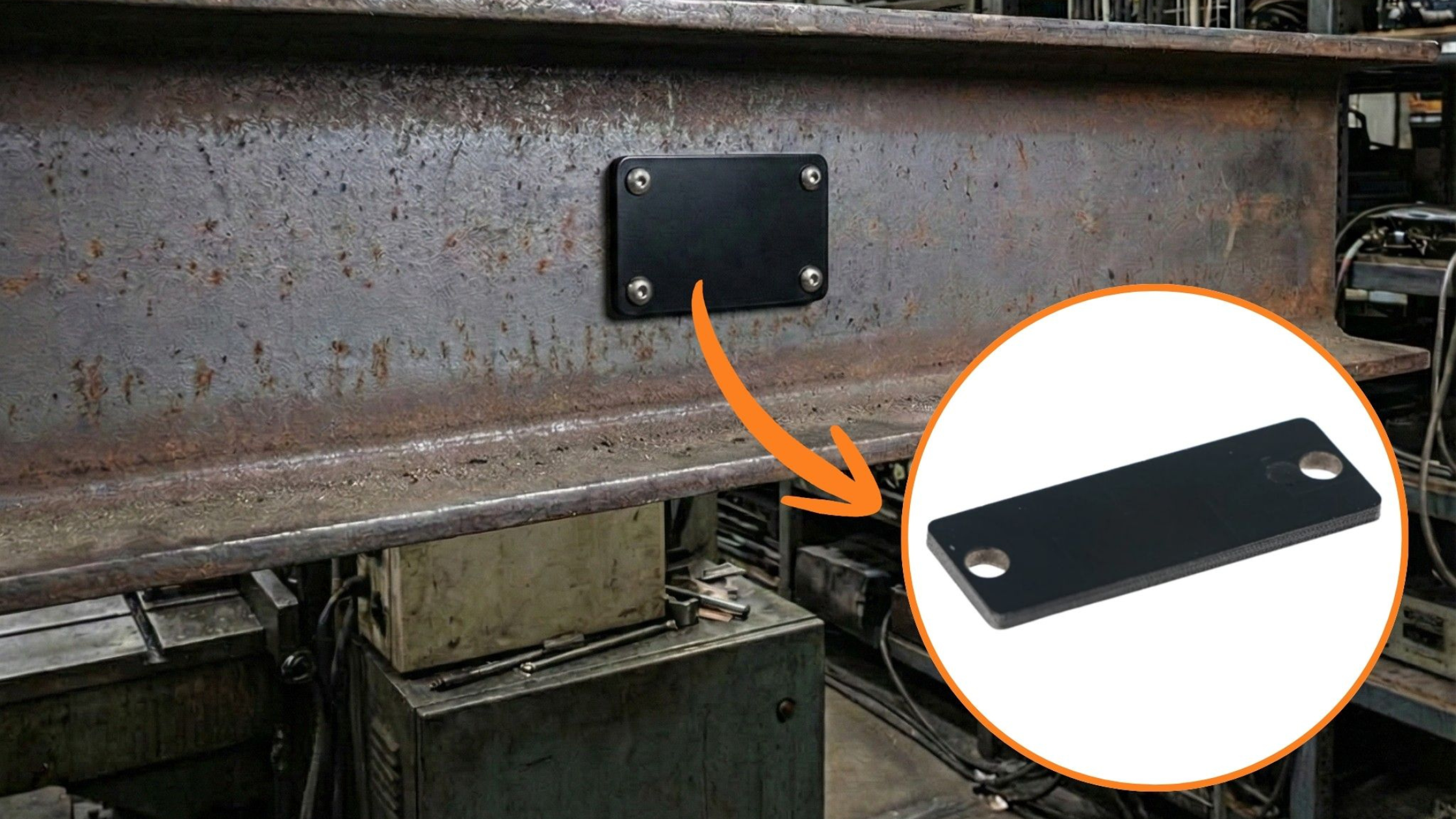

PCB on-Metal Tag: Understanding How They Work and Why They Matter

In industries that deal with metal assets, tracking tools, equipment, or products can be challenging. Traditional identification methods like barcodes often fail when applied to metal surfaces. This is where the PCB on-metal tag comes in. These specialized tags are designed to perform reliably on metal, making them essential for accurate asset tracking. In this blog, we will explain what PCB on-metal tags are, how they work, their applications, benefits, challenges, and tips for using them effectively.

What is a PCB on-Metal Tag?

A PCB on-metal tag is a type of RFID tag specifically engineered to attach to metal surfaces without losing performance. Standard RFID tags often fail on metal because metal interferes with the radio signal. These tags overcome that problem by integrating a printed circuit board (PCB) that isolates the antenna from the metal surface. This allows the tag to function correctly, providing accurate identification and tracking even in challenging environments.

In simple terms, a PCB on-metal tag is an electronic label that communicates wirelessly and works reliably on metal. Unlike traditional tags, these are built to handle the interference that metal surfaces usually cause.

How PCB on-Metal Tags Work

The key to the functionality of a PCB on-metal tag lies in its design. The tag consists of:

-

A PCB Layer: This layer separates the antenna from the metal surface.

-

Antenna: Responsible for receiving and sending signals.

-

Chip: Stores unique identification data.

-

Protective Housing: Protects the electronics from harsh environments.

When an RFID reader sends out a signal, the tag’s antenna captures it. The chip then responds with its stored information, allowing the system to identify and track the tagged object. The PCB layer ensures that the signal remains strong even when the tag is directly attached to metal.

There are different types of PCB on metal tags, including passive and active versions. Passive tags rely entirely on the reader’s signal for power, while active tags have their own power source, allowing for longer read ranges. Most industrial applications use passive tags due to their cost-effectiveness and durability.

Applications of PCB on Metal Tags

PCB on metal tags is widely used in industries where metal surfaces are common. Some typical applications include:

-

Manufacturing: Tracking tools, machinery, and returnable assets. Tags help prevent misplaced tools and improve workflow efficiency.

-

Automotive Industry: Monitoring metal parts and components during production and assembly.

-

Healthcare: Tagging surgical instruments, trays, and medical devices made of metal to ensure accurate traceability.

- Oil and Gas: Tracking equipment in harsh environments where durability is critical.

-

IT and Electronics: Managing servers, laptops, and other metal-heavy equipment.

These tags provide a reliable solution for environments where traditional labeling methods fail. They also integrate with inventory management systems to provide real-time tracking and reporting.

Benefits of Using PCB on Metal Tags

There are several advantages to using PCB on metal tags:

-

Reliable Performance on Metal: The primary benefit is that they work well on metal surfaces without interference.

-

Durability: Many tags are designed to withstand extreme temperatures, moisture, and physical impact.

-

Cost-Effective Tracking: Passive tags, in particular, provide a low-cost solution for high-volume applications.

-

Easy Integration: These tags can be easily incorporated into existing RFID systems.

-

Enhanced Asset Management: Organizations gain better visibility over tools, equipment, and inventory, reducing loss and downtime.

Additionally, RFID PCB on metal solutions can help automate processes, improve accuracy, and save time compared to manual tracking methods.

Challenges of PCB on Metal Tags

While PCB on metal tags offers many advantages, there are some challenges to consider:

-

Limited Range: Passive tags have shorter read distances compared to active tags.

-

Installation Considerations: Proper placement is crucial to avoid signal blockage.

-

Cost: Some high-performance tags can be more expensive than standard RFID tags.

-

Environmental Factors: Extreme chemicals or strong magnetic fields can still impact performance.

Understanding these challenges is important for selecting the right tag and planning its deployment effectively.

Tips for Using PCB on Metal Tags Effectively

To maximize the performance of PCB on metal tags, follow these practical tips:

-

Choose the Right Tag: Select a tag designed for your specific application and environment. Consider size, shape, read range, and durability.

-

Proper Placement: Avoid placing tags near corners or metal objects that could block signals. Some spacing from the surface may improve performance.

-

Test Before Full Deployment: Conduct pilot tests in the actual environment to ensure reliable reads.

-

Use Compatible Readers: Ensure your RFID readers support the frequency and type of PCB on the metal tag being used.

-

Maintain Records: Keep an updated database of all tagged items for accurate tracking and management.

Implementing these best practices helps organizations get the most value from their on-metal tags while minimizing potential issues.

Conclusion

PCB on metal tags is a vital tool for industries that need reliable tracking on metal surfaces. They work by using a PCB layer to isolate the antenna, ensuring strong signal performance. Widely applied in manufacturing, healthcare, automotive, and other sectors, these tags enhance asset management, reduce loss, and improve operational efficiency.

While there are challenges like installation and environmental considerations, careful planning and proper usage can overcome them. By following best practices, businesses can leverage RFID PCB on metal technology to maintain accurate records, streamline operations, and gain better control over their metal assets.

In today’s fast-paced industrial world, the PCB on-metal tag is not just a tool but a necessity for efficient, accurate, and reliable asset tracking. Contact Us.

Share:

NFC & HF RFID: The Practical Guide for RFID Labels and RFID Tags

Sustainable RFID: Smarter, Greener Supply Chains for Europe