The laundry business is under constant stress to enhance efficiency at a low cost. In the case of commercial wash processing thousands of items daily to hospitals that have to attend to patient laundry, the dilemma remains: how do you accurately track the inventory and still stay within the operational time limits? RFID in Laundry management has become a practical solution, providing an alternative to these pain points and providing measurable returns on investment.

The RFID Technology in Laundry Operations

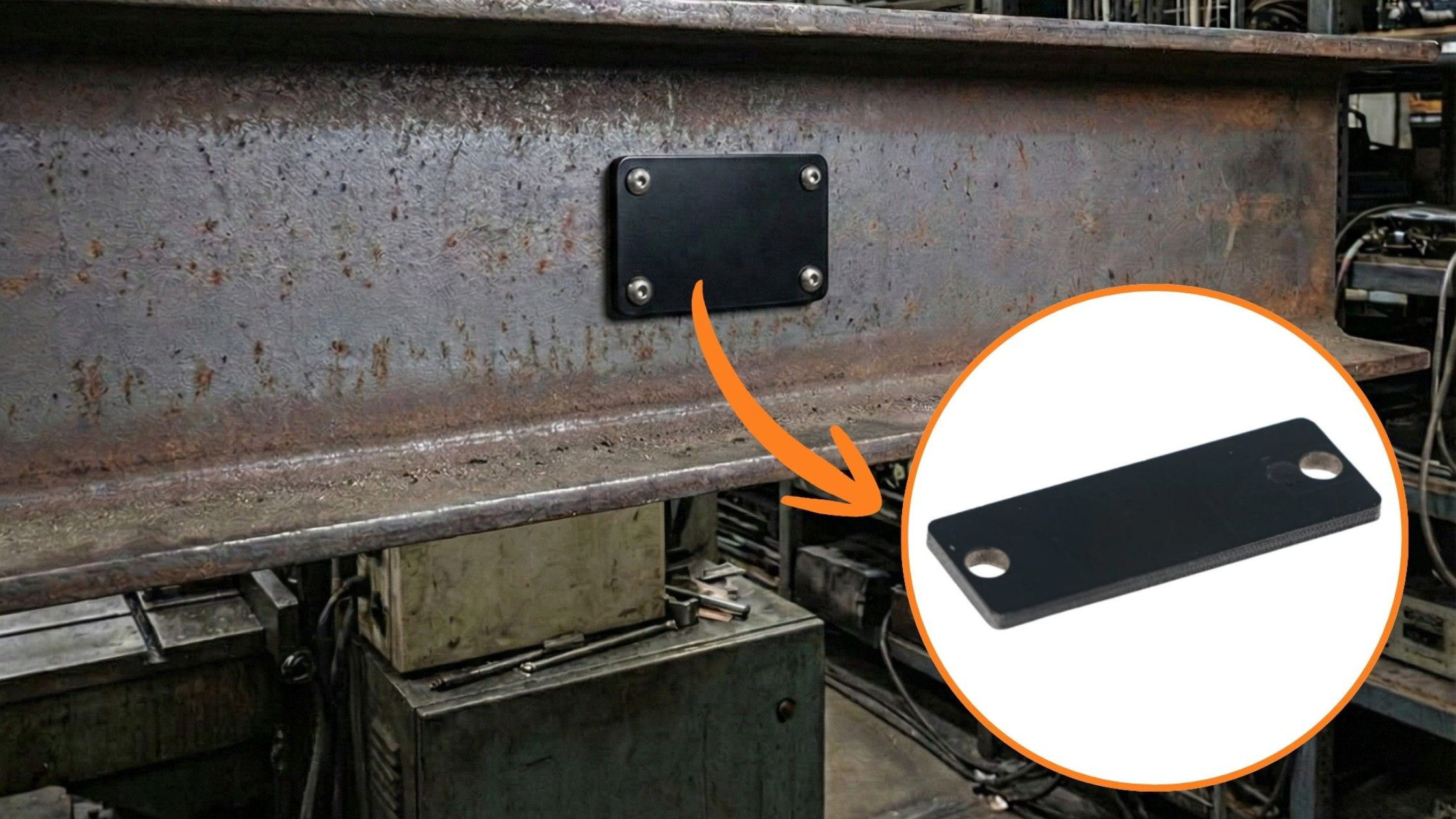

RFID Laundry tag for apparel contains a microchip and antenna that stores unique identification information. These tags can be scanned in large quantities, unlike traditional barcode systems, and they do not need a line-of-sight scan to be read and are thus suitable in large-volume laundry settings.

The technology has evolved significantly over the past decade. RFID laundry tags presently being used can resist extreme conditions of industrial washing, such as high temperature, chemical wash liquids, and mechanical stress. These durable laundry tags are able to withstand hundreds of laundry cycles and still maintain a high level of reliability, read rates, and hence an economical solution in terms of long-term tracking of assets.

How RFID Transforms Laundry Management

Manual counting and paper tracking systems hold much of the traditional form of laundry management. Such a method is time-consuming and also is likely to be subject to human error. The RFID clothing tags make the whole tracking process automatic, including the time when the goods are received at the facility, up to the time when the goods are being returned to their customers or departments.

When garments tagged with RFID laundry technology pass through strategically placed readers, the system automatically captures data about their movement. This will create a full audit trail that will be able to show wash cycles, processing time, and inventory. Staff can find particular items in seconds instead of spending much time searching for missing pieces.

The technology also enables providing the accurate billing for commercial laundry activities. Businesses can charge the customers using the precise number of items rather than making an estimate. This transparency strengthens the client relationships and removes disputes about whether there are any differences in invoicing.

Application in the Real World in Sectors

RFID clothing tags have been useful in healthcare facilities. Hospitals have huge numbers of linens, uniforms, and patient clothes that are required to be followed to comply with hygiene and limit expenses. RFID systems make sure that items undergo necessary washing and also comply with quality standards before they are able to go back into service.

The technology is used in hospitality businesses, including hotels and restaurants, with which they manage uniforms and table linens. Monitoring of individual items facilitates brand standards and also regulates the costs of replacement. The hotels may make sure that towels and beddings are of quality by having them checked before being used by the customers.

RFID laundry solutions have also been adopted by the industrial workwear services. Such businesses need to monitor orders of garments at a variety of customer locations and deal with complex billing systems. Automated tracking allows proper invoicing and service level agreement maintenance.

Laundry Operations Future-Proofing

The laundry business is constantly changing, and more and more attention is paid to sustainability and efficiency as well as transparency. RFID in Laundry management puts the businesses in a better position to fulfil these requirements and still succeed in the competitive market. With the RFID tag technology being further sophisticated and more affordable, the early adopters will have systems and processes already in place that the new competitors must work to match.

Investing in RFID infrastructure also demonstrates commitment to operational excellence, which increasingly matters to B2B customers who scrutinise their supply chain partners. The ability to provide detailed reporting and guarantee service quality through verifiable data strengthens business relationships in competitive markets.

Frequently Asked Questions

Q: How long do RFID laundry tags last?

RFID Laundry tags used in laundries are made of quality material and have a typical life of 200-300 laundry wash cycles, with high-end tags having a life of over 500 cycles. The shelf life is determined by the temperature at which it is washed, the exposure to chemicals, and mechanical forces during processing.

Q: What is the typical read range for RFID laundry tags?

The read range of most Laundry RFID systems is 1-5 metres (UHF, or Ultra High Frequency), depending on the power of the reader and the environment. This enables reading of items in bulk in trolleys or a conveyor system without any single handling.

Q: Are RFID laundry tags compatible with all fabric types?

RFID laundry tags can operate with the majority of textile materials. Nevertheless, the placement of tags is important; the placement of some garments is more effective. Manufacturers provide different types of tags, such as heat-sealed, sewn-in, and encapsulated tags that can be used in diverse applications.

Q: What are the advantages of RFID over barcode systems in tracking the laundry?

RFID has a number of benefits compared to barcodes: no line of sight, ability to read in bulk, resistance to adverse environments, and higher processing rates. Initial costs are more but the investment is usually rewarded in terms of operations in medium and large-scale operations.

Share:

Sustainable RFID: Smarter, Greener Supply Chains for Europe