UHF RFID Labels & Tags: Long-Range RFID Solutions

When it comes to high-speed, long-range identification, UHF RFID stands out as the global standard. From warehouses and retail stores to healthcare and logistics hubs, RFID labels and RFID tags using UHF frequencies are powering the next generation of automation.

In this article, we’ll break down how UHF RFID labels and tags work, what makes them unique, and where they deliver the greatest impact across industries.

What Is UHF RFID?

UHF stands for Ultra High Frequency, typically operating in the 860–960 MHz range. UHF RFID systems are known for:

-

Long read ranges (up to 10–12 meters)

-

High-speed bulk reading (multiple tags at once)

-

Compatibility with global EPC Gen2 and ISO 18000-6C standards

Because of these features, UHF is the dominant choice for passive RFID labels and tags used in high-volume environments.

UHF RFID Labels vs UHF RFID Tags: What’s the Difference?

-

RFID Labels: Thin, flexible, adhesive-backed inlays typically applied to packaging, boxes, cartons, and consumer goods. Ideal for logistics, retail, and supply chain tracking.

-

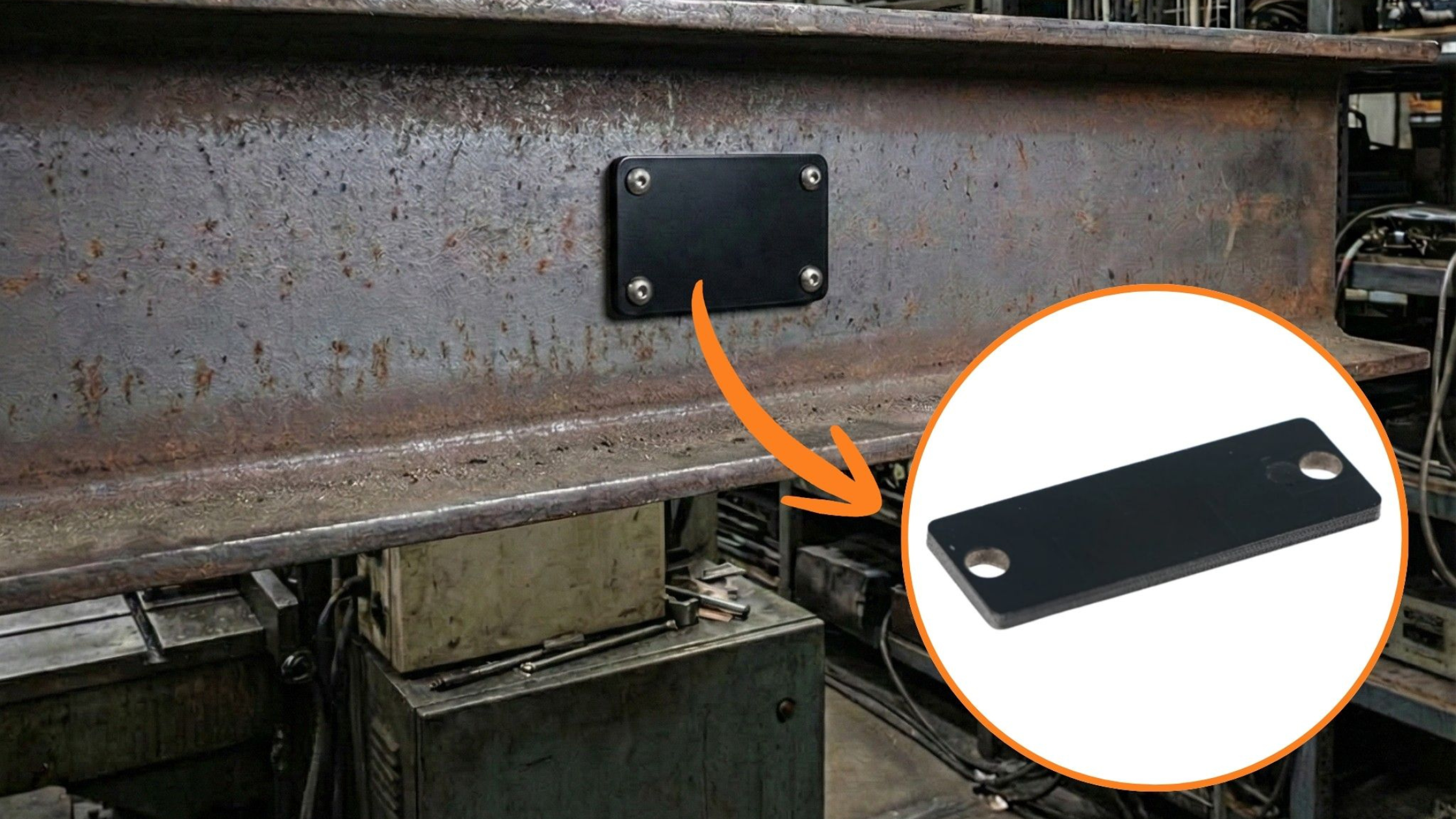

RFID Tags: More rugged, often encapsulated in plastic or metal housings. Designed for durability and longevity in harsh or industrial environments.

At TRC, we offer both from paper-thin UHF RFID labels for retail boxes to custom UHF RFID tags for pallets, assets, and metal surfaces.

Key Benefits of UHF RFID Labels and Tags

1. Long-Range Reading

Unlike LF and HF RFID, UHF can identify items from several meters away, even at speed. This makes it perfect for:

-

Conveyor belt scanning

-

Dock door portals

-

Inventory cycle counts in large areas

2. Bulk Item Detection

With UHF, hundreds of RFID labels or tags can be scanned in seconds without direct line of sight. Great for:

-

Fast stock audits

-

Automated receiving

-

High-throughput shipping zones

3. Global Standardization

UHF RFID is backed by EPC Gen2 and ISO standards, ensuring that your RFID labels and tags work across different systems and geographies.

When to Use UHF RFID Labels vs Tags

| Use Case | UHF RFID Label | UHF RFID Tag |

|---|---|---|

| Carton / item-level tracking | ✅ | |

| Retail inventory | ✅ | |

| Logistics / supply chain | ✅ | ✅ |

| Industrial environments | ✅ | |

| Metal surfaces or tools | ✅ (with on-metal RFID) | |

| High durability required | ✅ |

Custom UHF RFID Labels and Tags from TRC

Every application is different. That’s why TRC offers custom UHF RFID solutions tailored to your exact use case:

-

Custom form factors: Labels, hang tags, hard tags, and more

-

Encoding & printing: EPC, barcode, or QR code printed directly on RFID labels

-

Material compatibility: On-metal, high-heat, and outdoor variants available

-

Sustainable options: Paper-based, plastic-free UHF RFID labels also available

Whether you’re deploying RFID in a distribution center, retail environment, or factory floor, we help you choose the right mix of RFID labels and tags for maximum ROI.

Common Applications for UHF RFID Labels and Tags

-

Retail: Item-level tracking, shelf visibility, inventory accuracy

-

Logistics & Warehousing: Pallet and case tracking, cross-docking

-

Manufacturing: WIP (Work in Progress) monitoring, asset control

-

Healthcare: Equipment tracking, specimen labeling

-

Industrial & Tools: Using on-metal RFID tags to track assets in rugged conditions

Final Thoughts

As RFID adoption grows, UHF RFID labels and tags are becoming the standard for long-range, high-volume, and high-efficiency tracking.

With the ability to read multiple items at once, without line of sight, and at significant distance, UHF RFID outperforms traditional barcode systems and enables real-time visibility across the supply chain.

Whether you need flexible RFID labels or durable RFID tags, TRC delivers the performance, customization, and scalability your operation demands.

Need help choosing the right UHF RFID label or tag for your application?

Contact TRC for fast support, expert consultation, and tailored RFID solutions.

Share:

The Future of RFID Is Green: Eliminating Plastic Waste with Biodegradable RFID Labels

What Is an RFID Laundry Tag? The Ultimate Guide to Smarter, Longer-Lasting Textile Tracking